We help the world choose wisely, one game at a time.

Our mission is to radically improve decision-making in organizations,

from daily operations to long-term planning and strategy.

We aim to bring change because mediocrity in decision-making

is an option we cannot afford.

We care deeply about making the world better. We help lower emissions, save resources, uncover hidden opportunities, enhance customer service, and reduce costs.

Our solutions blend gaming principles with bespoke algorithms, self-learning AI, and highly tailored user interfaces. Each element is customized to maximize positive impact. Because when the stakes are high, settling for average is not an option.

The power of Game AI

Faster and better decisions

Chess grandmasters have used AI to master their game for years, yet businesses still make critical decisions using slow, biased methods and outdated spreadsheets. This is unacceptable.

Our solutions give you that same game-changing AI assistance, leading to step-change improvements in decision speed and quality.

Transparent and supportive

Just like chess bots, our game AI approach unveils new options for your business decisions and allows for transparent tradeoffs.

And just like chess grandmasters, you continue to play the game and remain firmly in control of your decisions.

Our process

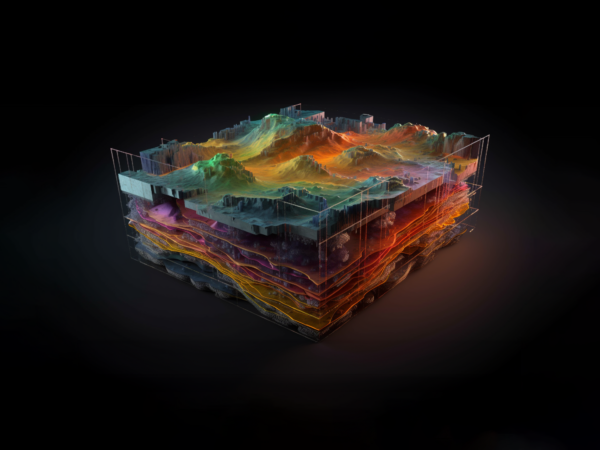

We use a simple and explainable 4-step approach that is focused on enabling better and faster business decisions.

Technology, mathematics, software and design all come together to serve that purpose.

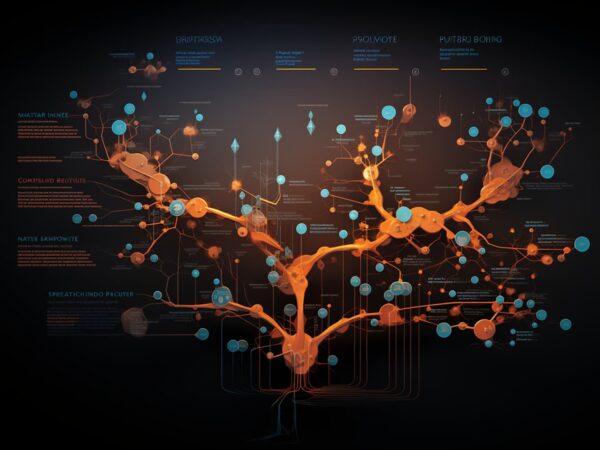

1. Game rules

We evaluate and translate business decisions into a game with elements such as moves, rules, and scores.

2. AI Assistant

Our custom algorithms and self-learning AI then learn to master that game.

3. Optimized Policies

The best strategies are extracted and tested against key uncertainties.

4. Business Decisions

Strategies are presented in a highly tailored user interface, giving you full and unbiased insight into options and tradeoffs, and allowing you to take the best possible business decision.

Solutions

We tackle challenges across industries, from energy and manufacturing to infrastructure, healthcare, finance, and logistics.

We aim for faster, better decision-making to speed up workflows, lower emissions, save operational cost and resources, improve execution, uncover hidden opportunities, enhance customer service, and reduce capital investment.